It was never an argument – climate change is real, and it demands urgent action. As per the IPCC 2018 Special Report on Global Warming of 1.5°C, it is estimated that by 2050, if the world isn’t fully carbon neutral, then global temperatures could increase by much more than 1.5C. However, as per Piers Froster, one of the lead authors of the landmark paper, there is still hope. He stated, “If the world can substantially reduce emissions in the 2020s and get to net zero carbon emissions by 2050, temperature rise can still be limited to 1.5C”.

This begs the question – how can we overturn climate change quickly and effectively? The surest way forward is geoengineering, which is essentially a way for human beings to manage the earth’s climate in deliberate ways. An effective, low cost way of geoengineering is to devise methods of Carbon Dioxide Removal, or CDR. Activities such as afforestation and reforestation are popular methods of CDR, however, given the time scale it takes to cause real impact, it isn’t a practical method despite its obvious benefits.

It is for this reason that more and more scientific and institutional efforts are directed towards creating ways of achieving CDR in a highly effective and relatively low-cost manner.

Enter: Negative Emissions Technologies (NET)

The idea behind NETs is simple – It is to capture or sequester emissions in the manufacturing process or during deployment. By making Carbon Dioxide Removal such an intimate part of the process, NETs can cause immense impact with scale. Naturally, one area where NETs can cause a revolution is in construction. Not only does the built environment emit 45% of the world’s carbon emissions, construction materials such as cement, steel, and bricks are proven to cause detrimental effects to the global climate.

Thus, if building materials themselves can capture carbon dioxide, then two birds would well and truly be struck by one stone, given the increasing demand for housing and public infrastructure, and the need for more sustainable construction.

In the field of civil engineering, bio-based building materials have been studied as a means for capturing carbon dioxide, and vegetal concrete has gained immense popularity in recent times given the fact that it offers higher thermal insulation and carbon sequestration. Even more crucially, vegetal concretes are carbon negative in most cases. However, despite its obvious benefits, vegetal concrete is rarely as strong as traditional building materials. There is, of course, a solution to this, but first let’s understand what makes vegetal concrete carbon negative in the first place.

How is vegetal concrete carbon negative?

The answer is simple – photosynthesis.

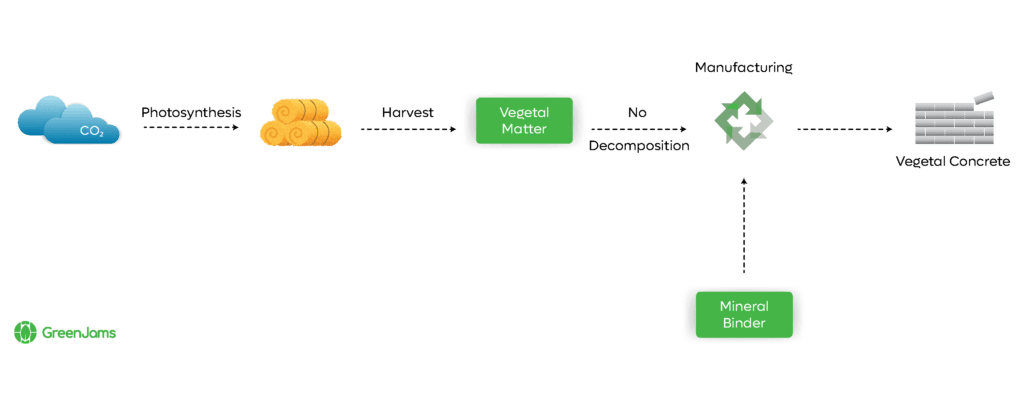

Vegetal concrete is made from refused plant matter such as hemp stalks, straw, corn stalks and so on. Obviously, when this plant matter was still a part of a plant that was rooted and irrigated, the plant absorbed CO2 from the air and converted it to long-chain phytocompounds such as cellulose, pectin and so on, with the energy offered by sunlight. In fact, for every 1g of carbon fixated in a plant 3.66g of carbon dioxide is absorbed from the air. As an example, it is found that roughly 43.4% of the mass of a rice plant is carbon. This means that in every 1kg of rice straw, there is 434g of carbon which is a result of the plant absorbing 1.6kg of carbon dioxide from the air.

Clearly then, vegetal concrete is the way to go given how it offers the same, if not better, strength, durability and insulation as typical concrete. However, the challenge isn’t just with processing the vegetal matter, but also with creating a binder that leaves a very low carbon footprint. That is because vegetal concretes are made of two components: vegetal matter and a mineral binder. The vegetal matter is chemically bonded with the mineral binder before it is decomposed, causing the fixated carbon to be locked away in a mineral matrix which the binder creates.

The carbon negative nature of vegetal concrete is largely a result of the vegetal matter. However, typical binders such as hydrated lime, hydraulic lime and lime pozzolana blends, are all detrimental to the environment. So there is a need to not only repurpose vegetal matter, but also create a mineral binder that has a very low carbon footprint. That way, the carbon-negative impact of the vegetal concrete is maximised.

That’s where GreenJams comes in

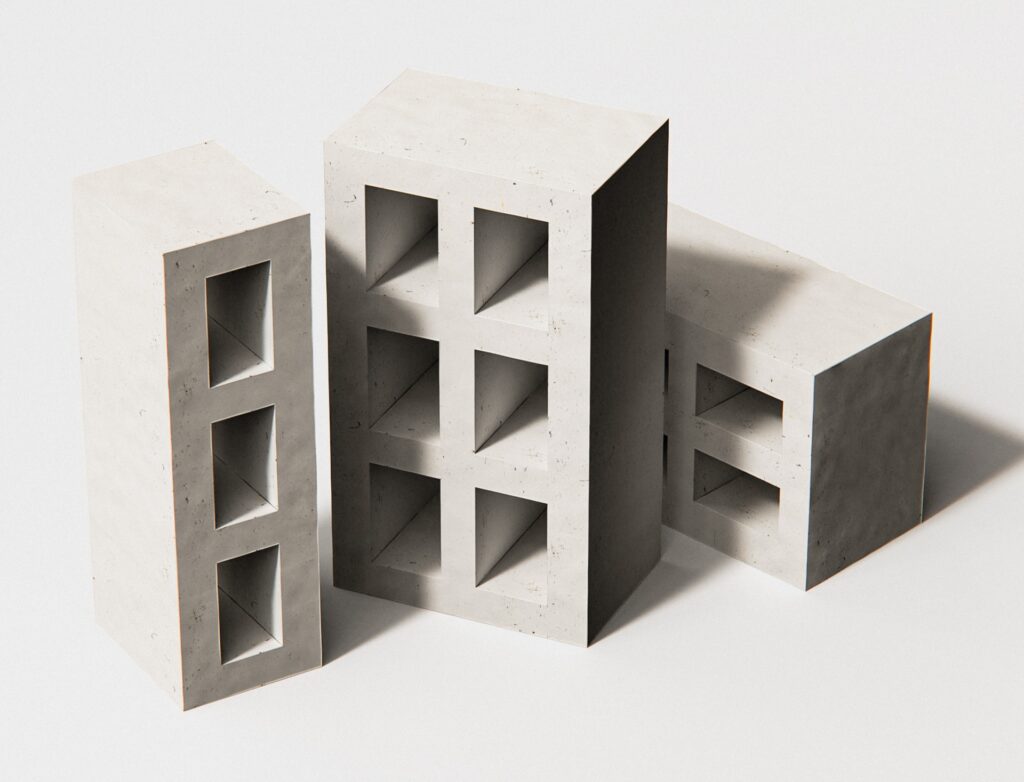

GreenJams have created a patented vegetal concrete called Agrocrete®, which is not only comprised of discarded plant matter that would otherwise be burnt, but also uses a revolutionary mineral binder called BINDR™, which is made from by-products of steel manufacturing such as non-toxic slag. BINDR™ only has 0.1kg CO2/kg of embodied carbon, which is 5 to 8 times lesser than the embodied carbon of lime and cement. Crucially, GreenJams makes vegetal concrete the obvious choice for residential, commercial and industrial use because Agrocrete is just as strong as traditional concrete while being carbon negative.

Through a patented manufacturing process, BINDR™ is combined with crop residues and as a result, the carbon-negative construction material, Agrocrete® is created.

The manufacturing process that GreenJams employs is a low-energy, low-resource process which can easily be plugged into renewable energy sources. Currently the company uses no fuels or energy other than electricity from the public power grid. Moreover, the water consumed in the treatment of the raw materials can be re-used for agriculture since it is rich with nutrients.

Building a better tomorrow

Considering that nearly 90% of the buildings and infrastructure needed by 2030 haven’t been constructed yet, the world needs more solutions like Agrocrete®. While there is always going to be more solutions to be created and more industries to revolutionise, it is worth pausing to take stock of the environmental impact we could make by adopting greener, more sustainable practices that don’t take anything from the environment, but give back to it.